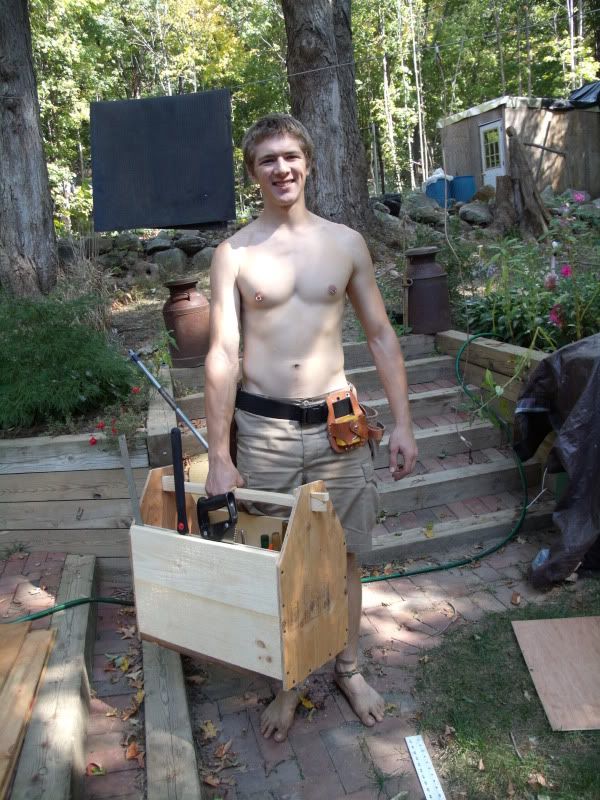

Up until an hour ago, this is what the shelf against the back wall of my shop looked like, but the box of small scraps was on the bottom shelf. That poor little cardboard box has been overflowing with little nearly-useless bits of nice wood for quite a while now, and spilling out onto the floor. Yesterday I finally did something about it and made a drawer for that bottom shelf that would hold plenty of scraps (as well as the small scrap metal box on the shelf in the left corner). I elected to use some of the wide Yellow Pine boards I got the other day, so I cut the pieces to length, shot the ends, laid out some half blind dovetails on the front and regular dovetails on the back, and went to work with the saw and chisel. Because this is a piece of shop furniture and I don't really care about appearances, I went fast and the joints show it. I would have just nailed the thing together, but I needed the practice on half blind dovetails (I've only cut one on some scrap before). I did nail the bottom in with some cut nails, because I don't have a plow plane (which will need to change in the near future).

The completed drawer in it's new home, being very useful:

In the above photo you can also see a few things that could be interesting, depending on your interests. On top of the shelf I have two boxes, the bottom of which holds several axes. The top box holds my Narex mortise chisels, my Lee Valley scrub plane, my Lee Valley carcass saw, and I have my two favorite axes resting on top. There is also a plate of glass that I set there to get at something else. The top shelf holds all of my glues and finishes, which doesn't really amount to much, but there it is. The middle shelf (from left to right) holds my stapler, the dremel, a box of various drill and driver bits, a box of timberlock screws, some half-finished spoons, and a tackle box holding all of my screws and nails. To the right of the shelf I have all of my hardwood, mostly Maple that I milled myself, but also a little Cherry and a couple pieces of some mystery wood that could be Mahogany. Just out of the picture on the right is my hot water heater.

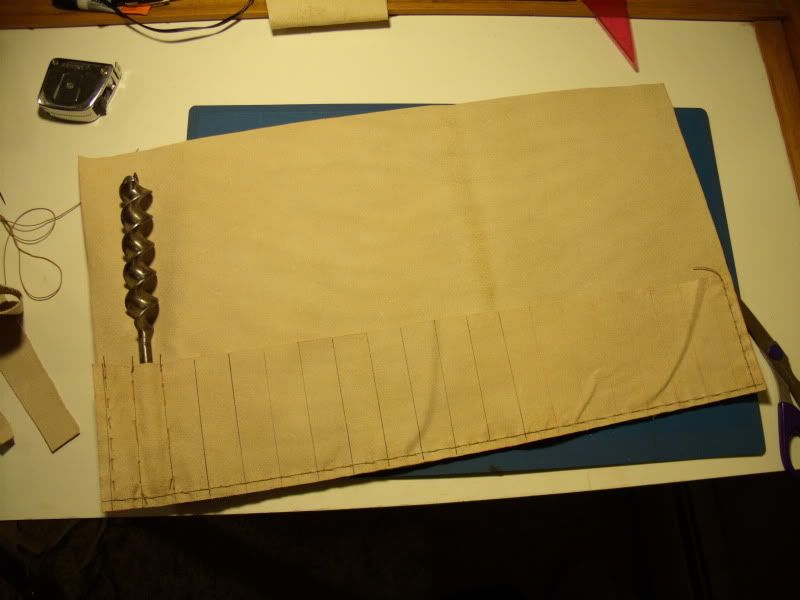

A friend of mine approached me about building a storage solution for her DVD collection, which is currently about 320 strong. I have been drawing up ideas based on 400, to allow for some growth. We met up last night to see which of the ideas she likes most, and we settled on a fairly basic frame and panel design. This unit will end up being about 68" tall and about 36" wide, so it will be no small thing. Right now we're leaning toward Cherry for the carcass and a high quality plywood for the panels, with glass in the doors. The curved sides are due to the distortion in my camera lens, all the lines are supposed to be straight. I'm thinking I'll aim for the main carcass pieces to be 3" wide on the face, with the door frame about 2" wide. On the scale drawing it looks about right to my eye. I think I'll want to use knife hinges to keep the clean lines on the front, but I'm not sure what to do about pulls for the doors yet. Maybe a couple of those things that allow you to press the door in, and then it springs out. I'm definitely going to need a plow plane for this project.